Others

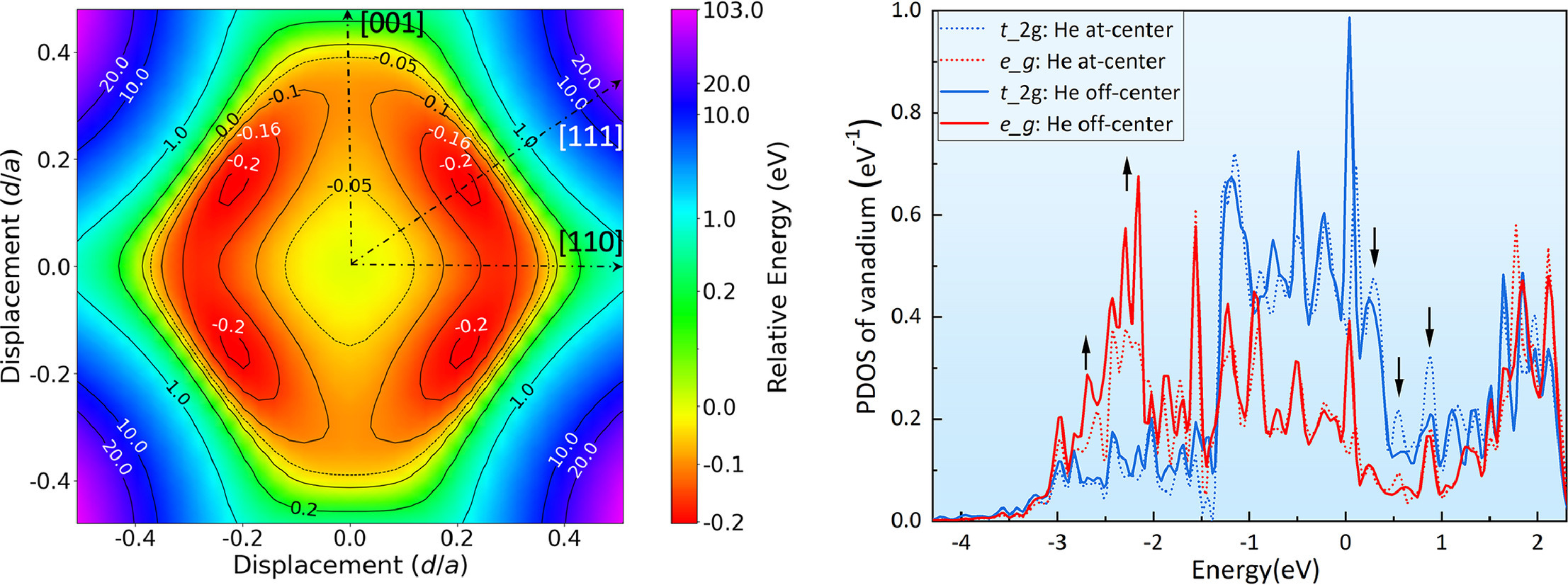

J.L. Cao, W.Q. Xie, J.B. Lin, X.F. He, V. Wang, Shigenobu Ogata, W.T. Geng,“Off-center positioning of helium in a vacancy in metals”, Journal of Nuclear Materials, 592 (2024) 154965-1-6.

It is a conventional wisdom that the closed-shell structure of a He atom prompts it to occupy the center of a vacancy in metals where the charge density is the lowest. Although it was found accidentally by density functional theory (DFT) calculations that the He sits off-center in a vacancy in vanadium (V), the underlying physics has remained elusive. We have performed systematic DFT study of the positioning of He in a vacancy in 40 elemental crystals, including alkali, alkaline-earth, and transition metals. We find that in addition to V, the off-vacancy-center positioning of He also occurs in Sc, Y, Ti, and Lu. Analyses of electronic structure reveal that d-orbital splitting and density of states (DOS) of the neighboring metal atoms at the Fermi surface play key roles in determining the position of He in a vacancy. Large t2g - eg splitting and high DOS at the Fermi surface provide the force to drive the He off the center of a vacancy, by compensating the repulsion from the metal atoms to which the He atom is approaching. This discovery adds new knowledge of the behavior of the noble gas atoms in non-uniform electron gas, provides fundamental reference energetics for the development of interatomic potentials, and shed light on understanding the initial stage of He bubble nucleation in materials used in nuclear reactors.

Back to topLuyao Wang, Shaojie Zhou, Kai Yang, Weiwei Huang, Shigenobu Ogata, Lei Gao, and Xiong Pu,“Screening Selection of Hydrogen Evolution-Inhibiting and Zincphilic Alloy Anode for Aqueous Zn Battery", Advanced Science, - (2024) 2307667-1-9.

The hydrogen evolution reaction (HER) and Zn dendrites growth are two entangled detrimental effects hindering the application of aqueous Zn batteries. The alloying strategy is studied to be a convenient avenue to stabilize Zn anodes, but there still lacks global understanding when selecting reliable alloy elements. Herein, it is proposed to evaluate the Zn alloying elements in a holistic way by considering their effects on HER, zincphilicity, price, and environmental-friendliness. Screening selection sequence is established through the theoretical evaluation of 17 common alloying elements according to their effects on hydrogen evolution and Zn nucleation thermodynamics. Two alloy electrodes with opposite predicted effects are prepared for experimental demonstration, i.e., HER-inhibiting Bi and HER-exacerbating Ni. Impressively, the optimum ZnBi alloy anode exhibits one order of magnitude lower hydrogen evolution rate than that of the pure Zn, leading to an ultra-long plating/stripping cycling life for more than 11 000 cycles at a high current density of 20 mA cm−2 and 81% capacity retention for 170 cycles in a Zn-V2O5 pouch cell. The study not only proposes a holistic alloy selection principle for Zn anode but also identifies a practically effective alloy element.

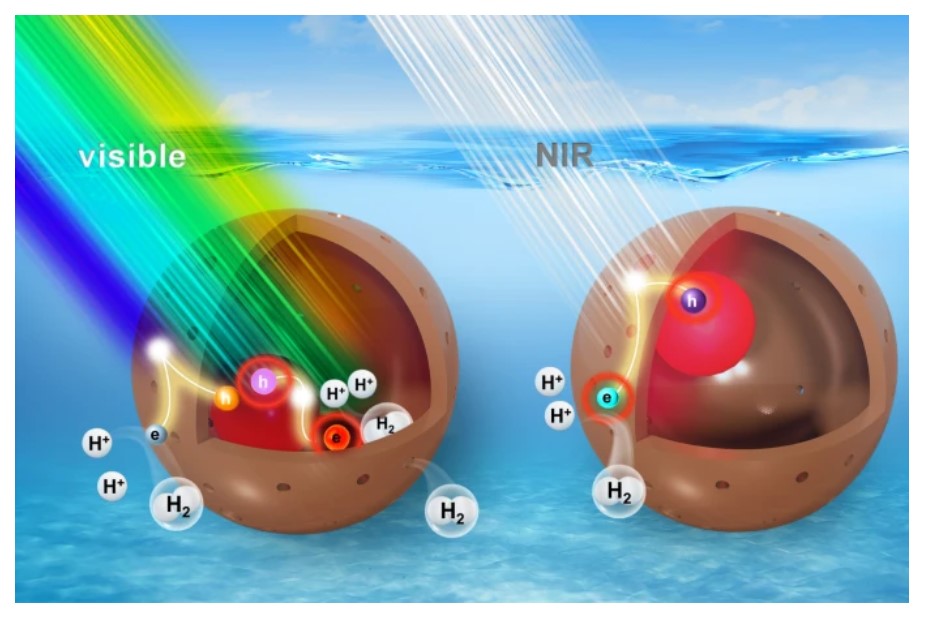

Back to topChun-Wen Tsao, Sudhakar Narra, Jui-Cheng Kao, Yu-Chang Lin, Chun-Yi Chen,Yu-Cheng Chin, Ze-Jiung Huang, Wei-Hong Huang, Chih-Chia Huang, Chih-Wei Luo, Jyh-Pin Chou, Shigenobu Ogata, Masato Sone, Michael H.Huang, Tso-Fu Mark Chang, Yu-Chieh Lo, Yan-GuLin, Eric Wei-Guang Diau, Yung-Jung Hsu, "Dual-plasmonic Au@Cu7S4 yolk@shell nanocrystals for photocatalytic hydrogen production across visible to near infrared spectral region", Nature Communications, 15 (2024) 413-1-13.

Near infrared energy remains untapped toward the maneuvering of entire solar spectrum harvesting for fulfilling the nuts and bolts of solar hydrogen production. We report the use of Au@CU7S4yolk@shell nanocrystals as dual-plasmonic photocatalysts to achieve remarkable hydrogen production under visible and near infrared illumination. Ultrafast spectroscopic data reveal the prevalence of long-lived charge separation states for Au@CU7S4 under both visible and near infrared excitation. Combined with the advantageous features of yolk@shell nanostructures, Au@CU7S4 achieves a peak quantum yield of 9.4% at 500 nm and a record-breaking quantum yield of 7.3% at 2200 nm for hydrogen production in the absence of additional co-catalysts. The design of a sustainable visible- and near infrared-responsive photocatalytic system is expected to inspire further widespread applications in solar fuel generation. In this work, the feasibility of exploiting the localized surface plasmon resonance property of self-doped, nonstoichiometric semiconductor nanocrystals for the realization of wide-spectrum-driven photocatalysis is highlighted.

Back to topShubham Sharma, Akarsh Verma, Sanjay Mavinkere Rangappa, Suchart Siengchin, Shigenobu Ogata, "Recent progressive developments in conductive-fillers based polymer nanocomposites (CFPNC’s) and conducting polymeric nanocomposites (CPNC’s) for multifaceted sensing applications", Journal of Materials Research and Technology, 26, (2023) 5921-5974.

Conducting polymer nanocomposites (CPNC's) are promising materials for sensor devices possessing design pliability, good sensitivity, and low temperature operation. For producing conducting polymer nanocomposites with tunable morphology, the soft template procedure is one of the advantageous aspects as reported from in-depth literature. Since the diameter and aspect ratio of conducting-polymer nanomaterials have affected the charge-transport properties, hence, the fine tuning of their structures is important to enhance sensitivity. This review has focused on the CPNC's membranes, insulative-polymers with conductive-fillers based CPNC's (IPCFCPNC's) and conductive-fillers based polymer nanocomposites (CFPNC's) which have been incorporated in many prior literary sources including the usage of strain sensors in some sensing applications for detection pressure, gas humidity, etc. As the review sheds light on incorporating specific types of nanofillers, such as graphene or carbon nanotubes or conducting filling-agents, into the CPNC's membrane matrix and insulative-polymeric-matrices, it will be possible to improve their mechanical stability, enabling them to be used for high-performance sensing applications. In addition, the review has evident that by using advanced fabrication techniques, such as electrospinning, it is possible to create thin, flexible CPNC's membranes that exhibit high sensitivity and stability towards target analytes. Therefore, the feasibility of CPNC's, IPCFCPNC's, and CFPNC's in sensor applications has thoroughly been reviewed for the purpose to realize the novel flexible CPNC structures and their other aspects of applications that may cater to new horizons in high-end smart flexible sensing applications. Additionally, the advanced discovery is to combine conductivity measurement and rheology analysis using a new emerging class of CPNC's, IPCFCPNC's, and CFPNC's for remarkable electrical properties. It is highly appealing to find out more about novel CPNC's, IPCFCPNC's, and CFPNC's, and their role in sensor matrices, considering their unique properties. Based on conducting polymers (CPs), and insulative-polymers with conductive filling-agents that have been reported during the past forty years, the properties and performance of sensing matrices have been investigated by incorporating the diverse carbon-based nano-additives and other nano filling-agents. Furthermore, another area of interest is the use of CPCs, and insulative-polymers with conductive filling-agents for the development of bio-sensors. CPCs, and insulative-polymers with conductive filling-agents can be functionalized with biological molecules such as enzymes, antibodies, and nucleic acids, to create highly sensitive sensors for the detection of various biological markers, including glucose, lactate, and pH. Along with myriads of illustrations in accordance with the CPs and their composites with nanoparticles, carbon materials, or conductive filling-agents with insulative-polymeric-matrices etc., their salient characteristics have been enumerated in this comprehensive review. Additionally, CPNC's, IPCFCPNC's, and CFPNC's-sensing devices will have to improve their analytical performance for a widespread spectrum of multifaceted sensing applications in future research trends.

Back to topYangen Li, Rui Li, Qing peng, Shigenobu Ogata, "Reduction of dislocation, mean free path, and migration barriers by high entropy alloy: insights from atomistic study of irradiation damage of CoNiCrFeMn", Nanotechnology, 31, 42 (2020) 425701-1-8.

High entropy alloy has attracted extensive attention in nuclear energy due to the outstanding irradiation resistance, partially owing to the sluggish diffusion. The mechanism from defect-generation aspect, however, has received much less attention. In this paper, the formation of dislocation loops, and migration of interstitials and vacancies in CoNiCrFeMn high entropy alloy under consecutive bombardments were studied by molecular dynamics simulations. Compared to pure Ni, less defects were produced in the CoNiCrFeMn. Only few small dislocation loops were observed, and the length of dislocation was small. The dislocation loops in Ni matrix were obviously longer, and so was the length of dislocation. The interstitial clusters had much smaller mean free path during migration in the CoNiCrFeMn. The mean free path of 10-interstitial clusters in CoNiCrFeMn was reduced over 40 times compared to that in pure Ni. In addition, CoNiCrFeMn had smaller difference of migration energy between interstitial and vacancy, which increased the opportunity of recombination of defects, therefore, led to less defects and much fewer dislocation loops. Our results provide insights of the mechanism of irradiation resistance in the high entropy alloy and could be useful in material design for irradiation tolerance and accident tolerance materials in nuclear energy.

Back to topNobuhiro Tsuji, Shigenobu Ogata, Haruyuki Inui, Isao Tanaka, Kyosuke Kishida, Si Gao, Wenqi Mao, Yu Bai, Ruixiao Zheng, Jun-Ping Du, “Strategy for managing both high strength and large ductility in structural materials–sequential nucleation of different deformation modes based on a concept of plaston”, Scripta Materialia, 181 (2020) 35-42.

Based on recent findings in ultrafine grained metals, we proposed a strategy for overcoming the strength-ductility trade-off in structural metallic materials. Sequential nucleation of different deformation modes, such as unusual slip systems, deformation twinning, martensitic transformation, etc., would regenerate strain-hardening ability of the material, leading to high strength and large tensile ductility. For discussing the activation of different deformation modes in atomistic scales, the concept of plaston which considered local excitation of atoms under singular dynamic fields was proposed.

Back to topLei Wang, Chun Feng, Mi-Dan Cao, Fei Meng, Yu-Kun Li, Jian-Juan Yin, Bao-He Li, Shigenobu Ogata, Wen-Tong Genga, Guang-Hua Yu, “Synergistic effect of lattice strain and Co doping on enhancing thermal stability in Fe16N2 thin film with high magnetization”, Journal of Magnetism and Magnetic Materials, 495 (2020) 165873.

Single phase Fe16N2 is a potential material in building high-performance magnetic writing heads and permanent magnets due to its ultra-high saturation magnetization (MS) and magnetic anisotropy (Keff). However, the poor controllability of phase constituent and low thermostability (decomposed at 200 °C) are big obstacles to its practical applications. In this work, we have devised a novel Fe/Cr/FeN:Co heterostructure to introduce both lattice strain and Co doping for tuning the FeN constituent and enhancing the phase stability synergistically. With effective regulation, the FeN layer can possesse both superior MS (2.4–2.8 T) and high thermostability with standing 450 °C annealing. Furthermore, by first-principles calculations, we reveal that the synergistic regulation on the thermostability is closely related to the solution heat tunability of Fe-N phases. The Fe/Cr/FeN:Co heterostructure may serve as a promising material for constructing high-efficient writing heads, permanent magnets, and other magnetic devices.

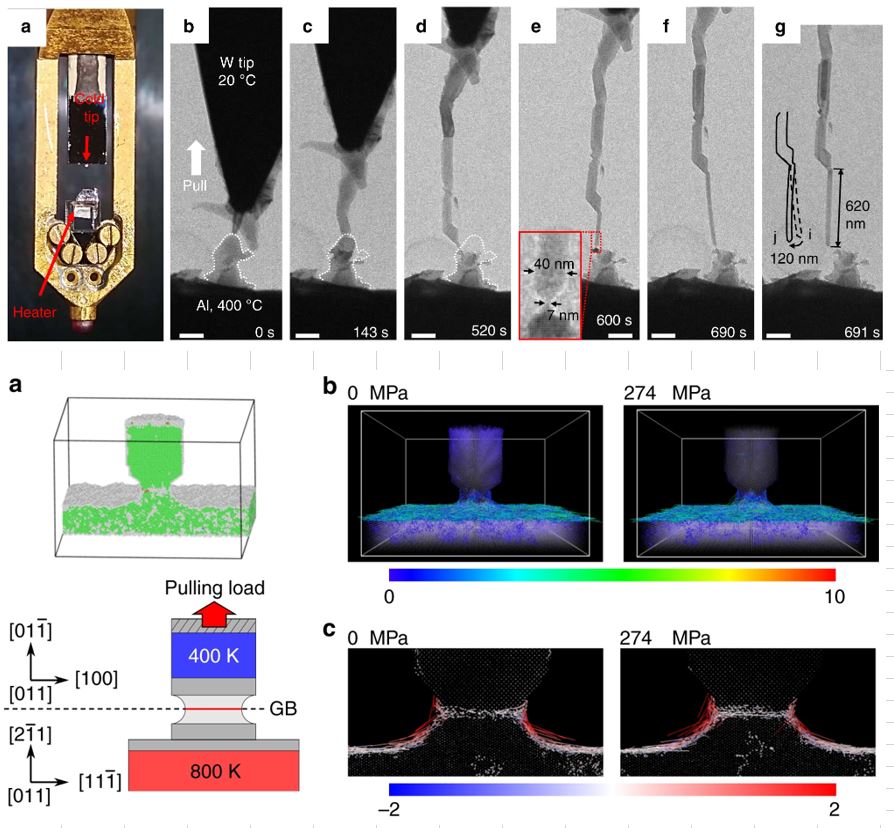

Back to topDe-Gang Xie, Zhi-Yu Nie, Shuhei Shinzato, Yue-Qing Yang, Feng-Xian Liu, Shigenobu Ogata, Ju Li, Evan Ma, Zhi-Wei Shan, "Controlled growth of single-crystalline metal nanowires via thermomigration across a nanoscale junction", Nature Communications, 10 (2019) 4478-1-8.

Mass transport driven by temperature gradient is commonly seen in fluids. However, here we demonstrate that when drawing a cold nano-tip off a hot solid substrate, thermomigration can be so rampant that it can be exploited for producing single-crystalline aluminum, copper, silver and tin nanowires. This demonstrates that in nanoscale objects, solids can mimic liquids in rapid morphological changes, by virtue of fast surface diffusion across short distances. During uniform growth, a thin neck-shaped ligament containing a grain boundary (GB) usually forms between the hot and the cold ends, sustaining an extremely high temperature gradient that should have driven even larger mass flux, if not counteracted by the relative sluggishness of plating into the GB and the resulting back stress. This GB-containing ligament is quite robust and can adapt to varying drawing directions and velocities, imparting good controllability to the nanowire growth in a manner akin to Czochralski crystal growth.

Back to topGuo-Jie Jason Gao, Jerzy Blawzdziewicz, Michael C. Holcomb, and Shigenobu Ogata, "Understanding the Local Flow Rate Peak of a Hopper Discharging Discs through an Obstacle Using a Tetris-like Model", Granular Matter, 21 (2019) 25-1-10.

Placing a round obstacle above the orifice of a flat hopper discharging uniform frictional discs has been experimentally and numerically shown in the literature to create a local peak in the gravity-driven hopper flow rate. Using frictionless molecular dynamics (MD) simulations, we show that the local peak is unrelated to the interparticle friction, the particle dispersity, and the obstacle geometry. We then construct a probabilistic Tetris-like model, where particles update their positions according to prescribed rules rather than in response to forces, and show that Newtonian dynamics are also not responsible for the local peak. Finally, we propose that the local peak is caused by an interplay between the flow rate around the obstacle, greater than the maximum when the hopper contains no obstacle, and a slow response time, allowing the overflowing particles to achieve a higher local area packing fraction by converging well upon reaching the hopper orifice.

Back to topChun Feng, Jianjuan Yin, Jian-Gang Niu, Qinghua Zhang, Lin Gu, Feng Yang, Xiaolei Tang, Longxiang Xu, Kui Gong, Yi Cao, Meiyin Yang, Xiaopeng Cui, Shigenobu Ogata, Wen-Tong Geng, and Guanghua Yu, "Construction of FeN alloy films with ultra-strong magnetism and tunable magnetic anisotropy for spintronic application", Journal of Alloys and Compounds, 725 (2017) 32-40.

FeN alloy film is a promising spintronic material with the theoretically ultra-strong magnetism (saturation magnetization MS and magnetic anisotropy Keff) and high spin polarization, which relies on the degree of N ordering interstice occupancy (S). However, due to the high activation energy for N ordering, the S value of an actual FeN film is mostly lower than 35% and this restricts the achievable magnetism and transportation property. Thus, the construction of a FeN alloy film with well-controlled magnetism and efficient electronic transportation remains a long-standing challenge. Here, we tackle the problem by strain engineering. Using an Fe/Cr underlayer, we introduced a considerable epitaxial strain in the FeN lattice. The strain is proven to effectively promote the S value to over 60%, resulting in remarkable enhancement of MS value from 2.18T to 2.81T (30% increment) and effective tunability of Keff value ranging 1.3~2.2 × 106 J/m3. Besides, the matched energy band symmetry (Δ5) between Cr and Fe16N2 facilitates the efficient electronic transportation for spintronic applications. By simulating interstice distribution with the first-principles calculations, the lattice strain is found to decrease the activation energy for N interstitial migration, which serves as a thermodynamic driving force for the magnetism tunability.

Back to topRyo Matsumoto, Takahiro Chida, and Shinji Hahami, "Indentation Joining Process with Bar Oscillation on Servo-controlled Press―Development of Plastic Joining Method Using Indentation III ―", The Japan Society for Technology of Plasticity, 51-593 (2010) 597-601. [in Japanese]

A plastic joining method for fixing bars with a hot-forged plate was proposed in previous papers. In this method, a cold bar is directly indented into a hot plate to pierce the plate without lubrication on a press and then fixed to the plate after piercing. In this study, to improve the bonding strength of a bar-plate, the indented bar was oscillated at amplitudes of 0.2 - 2.0 mm immediately after bar indentation into the plate on an AC servo-controlled press. The effect of bar oscillation on the bonding strength of the bar-plate was examined using an A6061 aluminum bar and an A6061 aluminum plate. The obtained shear bonding stress of the bar-plate in the indentation joining with bar oscillation of 0.2 mm of amplitude was approximately 1.5 times higher than that in the indentation joining without bar oscillation at an indentation temperature of 500 °C. The bonding mechanism of the indentation joining with bar oscillation was discussed from the viewpoints of bar-plate seizure and mechanical clam ping associated with the method.

Back to topRyo Matsumoto, Shinji Hanami, Kozo Osakada, and Hyoji Yoshimura, "Indentation Joining Process for Steel Bar - Aluminium Plate ―Development of Plastic Joining Method Using Indentation II―", The Japan Society for Technology of Plasticity, 50-587 (2009) 96-100. [in Japanese]

A new plastic joining method for fixing bars with a hot-forged plate was proposed, in which steel bars maintained at room temperature are directly indented into a high-temperature steel plate, as reported in a previous paper. To examine the validity of the developed plastic joining method, the optimum conditions of the plastic joining method are investigated using an SCM435 steel bar and an A5052 aluminium plate on a mechanical or AC servo-controlled press. It is possible to indent the bar to the plate without the buckling or plastic deformation of the bar at room temperature, and the attained shear bonding stress of the bar–plate is approximately 70% of the shear strength of the plate material. The bonding mechanism of the proposed plastic joining method is discussed from the viewpoints of plate seizure and mechanical clamping associated with the process.

Back to topRyo Matsumoto, Shinji Hanami, A. Ogura, H. Yoshimura, and Kozo Osakada, "New Plastic Joining Method using Indentation of Cold Bar to Hot Forged Part", CIRP Annals - Manufacturing Technology, 57-1 (2008) 279-282.

A new plastic joining method for fixing bars with a hot forged plate is proposed in which bars kept at room temperature are directly indented into a high-temperature plate. The optimum conditions for the proposed plastic joining method are examined using a low-alloyed steel bar and a carbon steel plate. It is possible to indent the bar to the plate without buckling or plastic deformation by keeping the plate above 850 °C. The attained shear bonding stress of bar–plate is approximately 40% of the shear strength of the plate material. The bonding mechanism of the proposed plastic joining method is discussed from the viewpoints of seizure of the plate and mechanical clamping associated with the process. Furthermore, some applications of the proposed method are suggested.

Back to top Ogata Laboratory

Ogata Laboratory